How To Filter And Vacumm Degas Acetonitrile

5-4) Vacuum Degassing Using a Gas-Liquid Separation Membrane

Degassing Methods

Vacuum Degassing Using a Gas-Liquid Separation Membrane

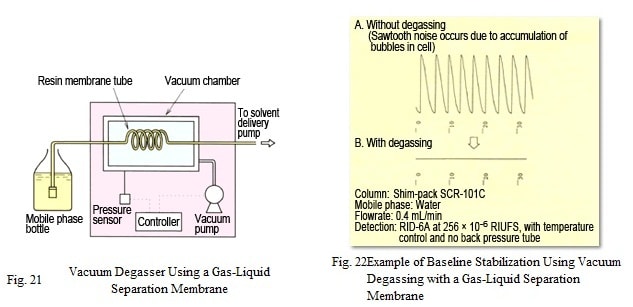

This type of Degassing Unit of measurement is installed between the mobile phase bottle and solvent commitment pump and is then widely used that it is commonly called a Degassing Unit. These Degassing Units maintain a vacuum pressure on the outside of a resin membrane tube and use the permeability of the membrane to remove smaller molecules, such as oxygen and nitrogen, from the mobile phase solution. Because they are able to remove about seventy to 95 % of the air, they are able to foreclose issues with bubble formation in catamenia lines, fifty-fifty for gradients, and they are suited to certain loftier-sensitivity detection methods.

Procedure

Connect the Degassing Unit to the mobile stage bottle and delivery pump. Drain virtually ii to 3 times the capacity of the resin membrane tube (about 15 mL per line for models DGU-3A/4A, ten mL for models DGU-12A/14A, or 2 mL for models DGU-12AM/14AM) via the pump drain. Alternatively, intentionally aspirate bubbles with a suction filter raised above the liquid surface for about v seconds as the effluent is drained, and await for bubbles to bleed out. After bubbling stop draining, continue draining nearly 10 mL, and and so complete the mobile phase replacement.

Advantages

- No restrictions on the mobile phase bottle shape or stopper (other online degassing methods take restrictions).

- The limerick of mobile phase mixtures are less likely to change.

- Operating cost is depression.

- Handling is like shooting fish in a barrel.

Disadvantages

- Degassing capacity depends on flowrate.*i

- Degassing chapters varies when switching the vacuum pump ON or OFF.*2

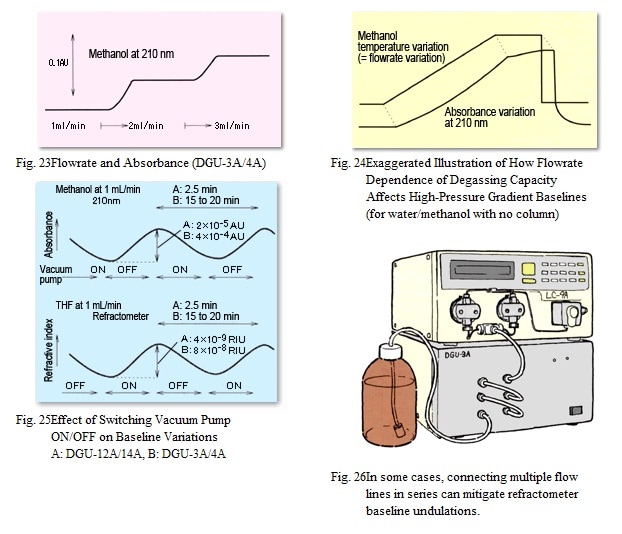

*1: Degassing capacity decreases the higher the flowrate. Therefore, if a 100 % methanol mobile stage is monitored at 210 nm, absorbance increases when the flowrate is increased (Effigy 23, using models DGU-3A/4A). During water/methanol high-pressure linear gradient analysis, the alter in baseline absorbance is a curved line (Effigy 24).

*two: There are three types of Degassing Units - (ane) models with vacuum pumps that rotate at a constant rpm, (2) models with vacuum pumps that shut off when the vacuum level inside the vacuum chamber reaches a certain level, then automatically restart when the vacuum level decreases again, and (three) models with vacuum pumps that switch ON and OFF at brusque fixed intervals. Type (1) models take an extremely long time to stabilize and non too many are being sold. Until now, many models were blazon (2) (DGU-3A/4A). In some cases, type (2) Degassing Units can cause undulations in baselines at 210 nm for methanol UV detection or 254 nm for THF refractometer detection (Figure 25). In more recent years, type (three) models (DGU-12A/14A) have appeared which crusade much lower undulation. For refractometers, undulations can sometimes exist reduced by connecting the multiple period lines from the Degassing Unit in series (Effigy 26).

Applications

- Loftier-precision (reproducibility of retention times) analysis using depression-pressure or high-pressure level gradient mixing

- High-sensitivity analysis using fluorescence detection, electric conductivity detection, or electrochemical detection

- Loftier-sensitivity analysis using UV detection. However, this method is non suitable if using mobile phases where fluctuations in dissolved oxygen levels significantly bear upon the absorbance.

- Normal-sensitivity analysis using refractometer detection.

| Annotation: | This folio is a partially revised html version of LCtalk Special Event 5 (1991). |

How To Filter And Vacumm Degas Acetonitrile,

Source: https://www.shimadzu.com/an/service-support/technical-support/analysis-basics/lib/lctalk/s5/054.html

Posted by: stewartfaturaved.blogspot.com

0 Response to "How To Filter And Vacumm Degas Acetonitrile"

Post a Comment